Packaging Auxiliary Items

We Offer Complete Equipment Solutions for Nearly Every Beverage Industry

Leave the details to ABE. When you partner with ABE, we ensure your craft beverage equipment needs are covered from start to finish. That means we provide complete beverage packaging equipment solutions with the same service and guarantee that led you to do business with us. Most of our turnkey solutions are designed and assembled by us, so you’ll know that your equipment will flow perfectly for simple and optimal beverage packaging.

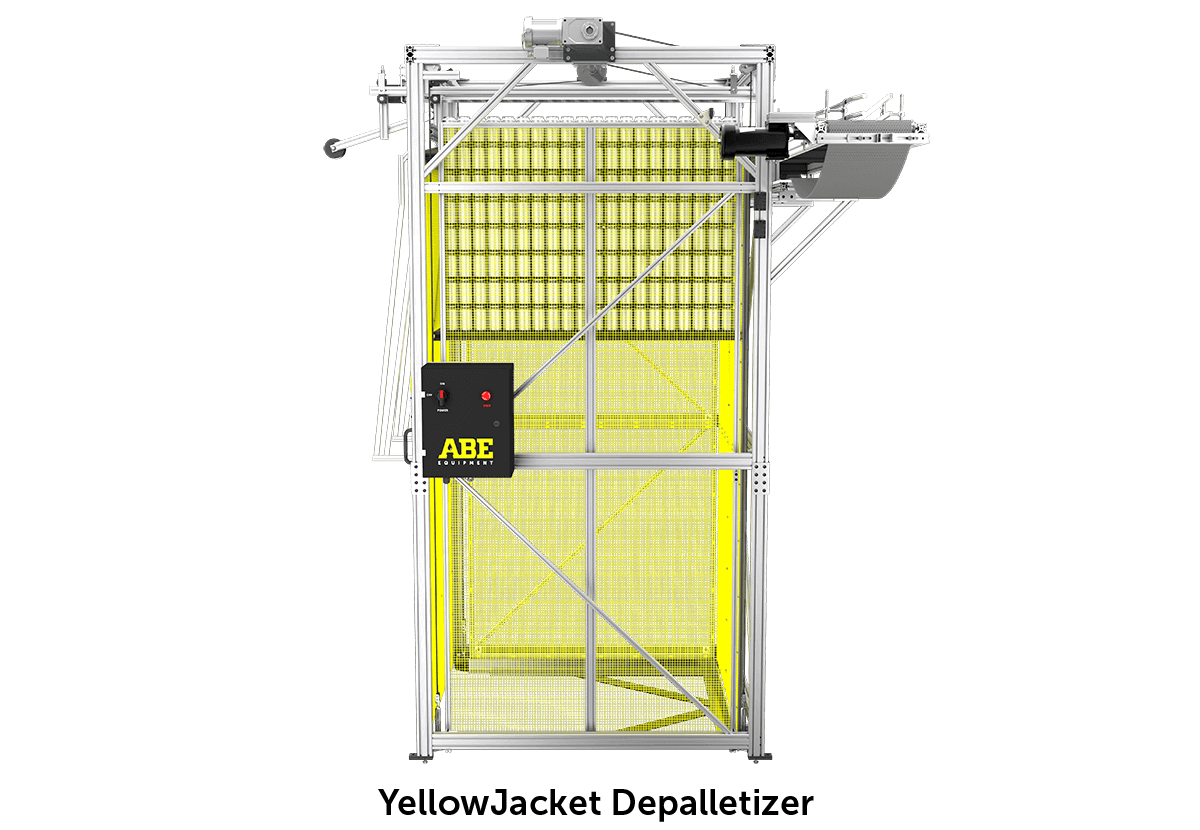

YellowJacket Depalletizer

Can Compatible

- Accepts standard pallet sizes

- Capable of full height or half height pallets

- Integrated slip-sheet storage

Ready for Your Operation

- Easily integrates into select canning lines for maximum operation control

- Pre-wired and pre-tested prior to shipment

- No air required

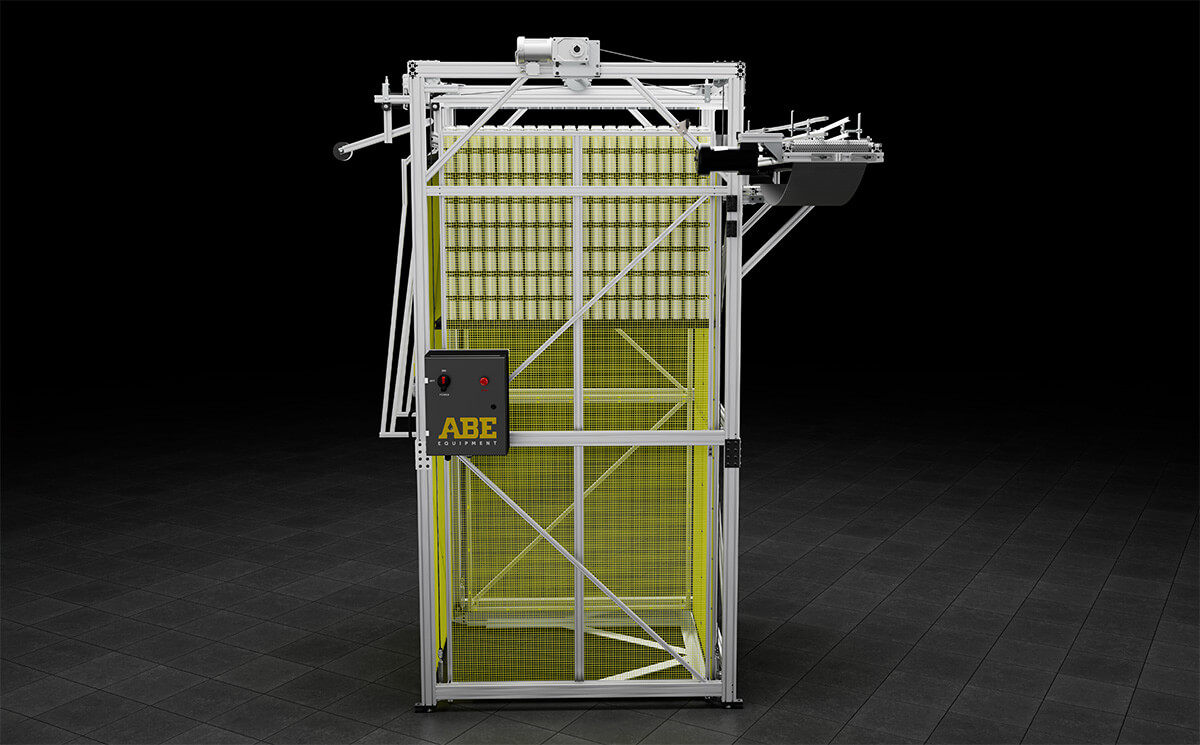

TailGator

Heavy-Duty Construction

- Sturdy stainless steel construction

- Adjustable leg height

- Meets CSA/UL and EU standards

Premium Features

- Tilts and vibrates to allow feeding into a TwistRinse

- Utilize can sizes up to 16.0 oz (500 ml)

- Allows for a full slip of cans

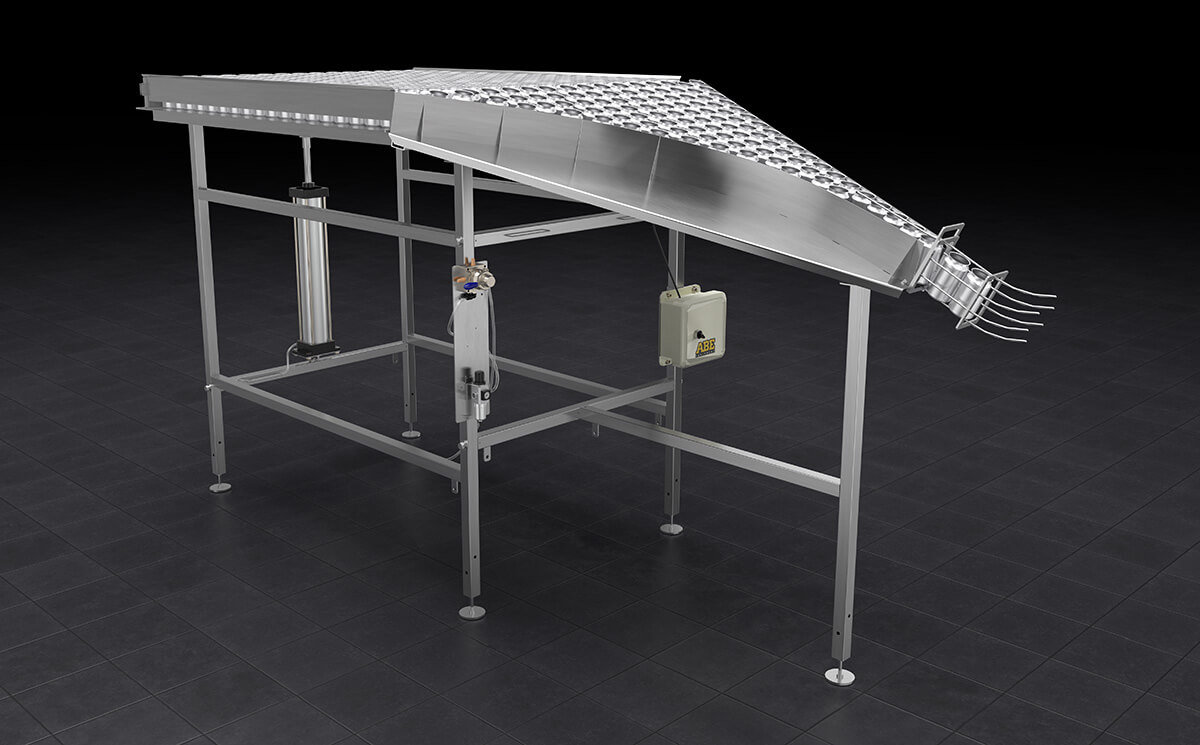

Feed Table

Specifications

- Designed to hold complete slip of empty cans for semi-automatic feed onto main canning line drive conveyor.

- Variable Speed Drive Control

- Max can size 16.9 oz (500ml)

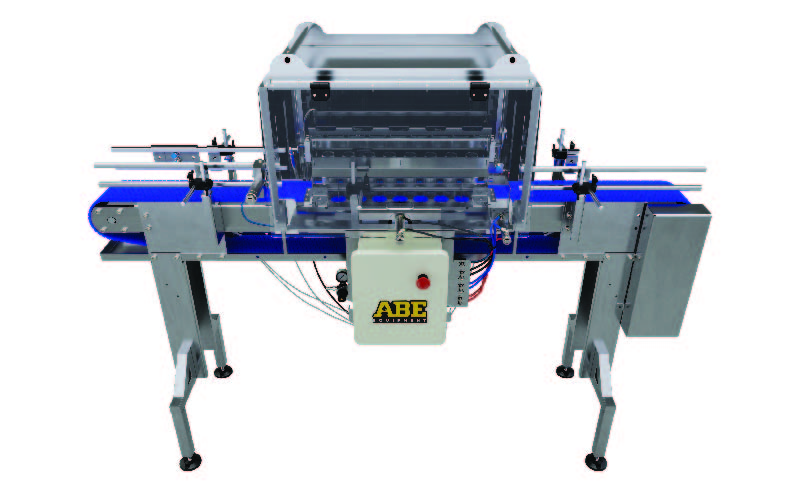

FlipRinse

Compatibility

- Two configurations

- Clean and Rinse 3 cans at 18 CPM

- Clean and Rinse 8 cans at 48 CPM

- Add to any CraftCan Canning Line

- Easily adjusts between standard, sleek, and slim cans

Compact & Efficient Design

- Two-second rinse cycles

- Use ionized air if desired

- Low water usage

- Adjustable water spray settings

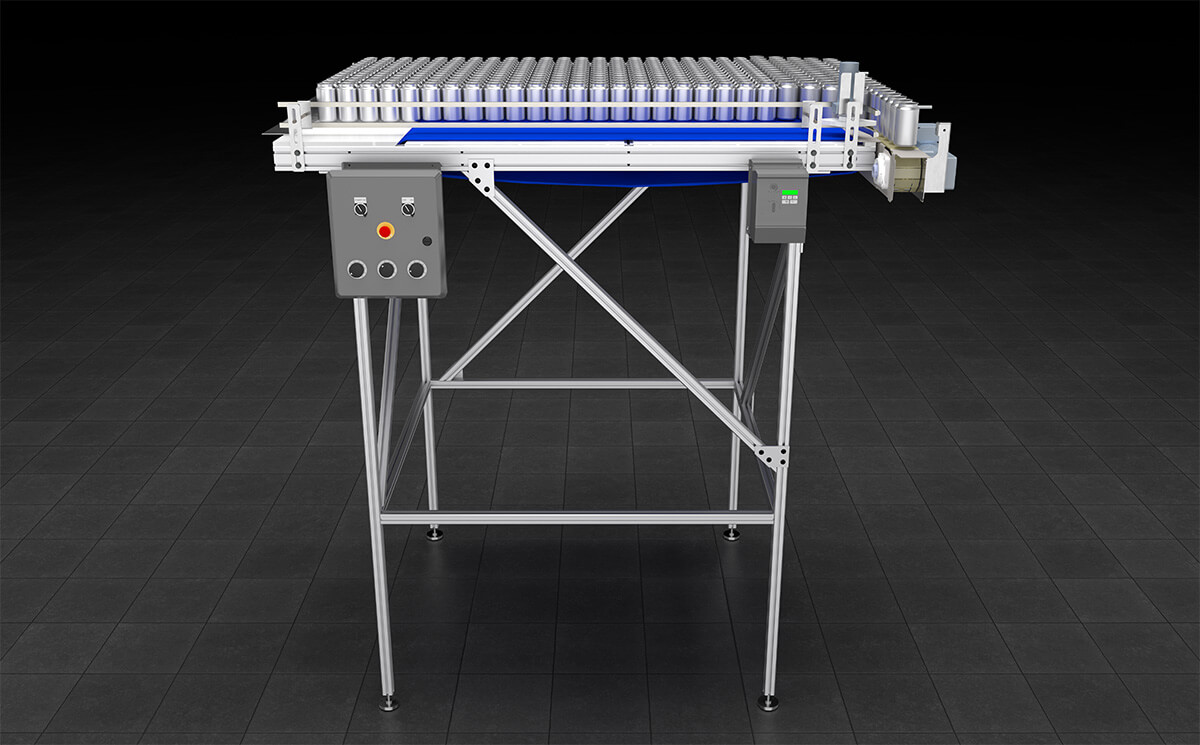

Pack Off Table

Specifications

- 8′ Pack-off

- 6′ Pack-off

- 4′ Pack-off

Features

- Durable stainless steel/extruded aluminum frame

- Dayton central drive motor

- Delron long-life conveyor material

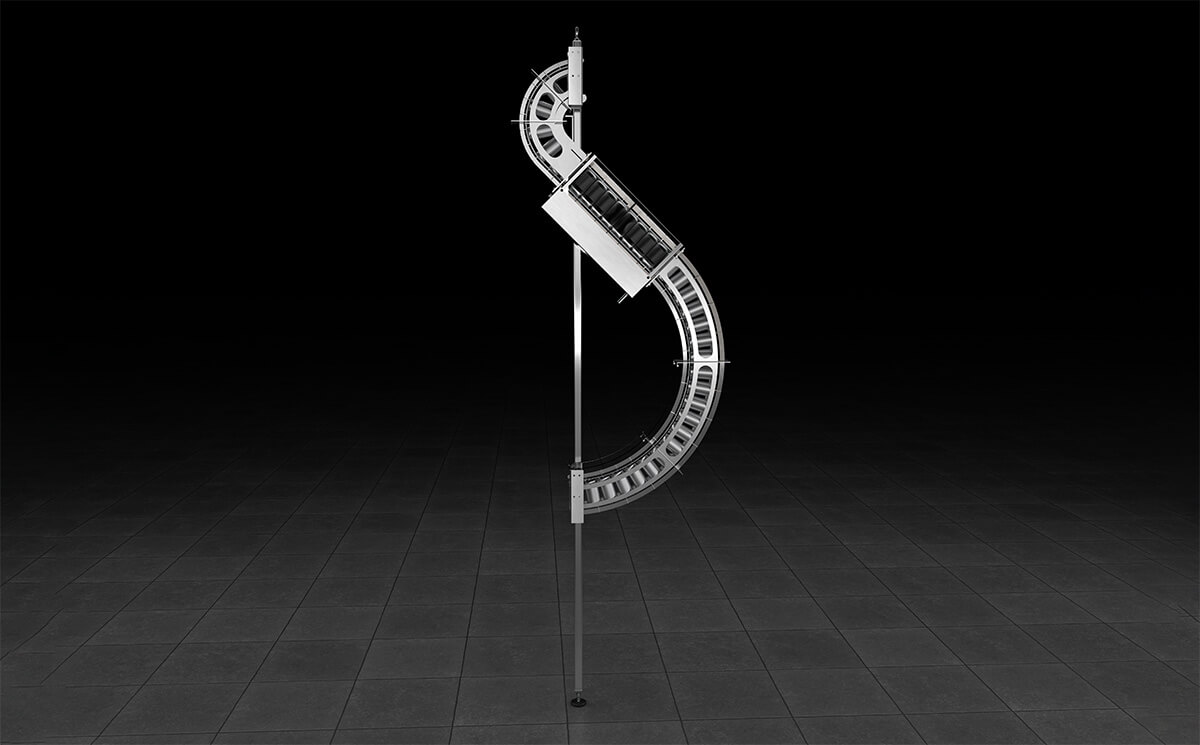

Rinse Solutions

Options

- Standard Twist Rinses

- Zero Footprint twist rinses

- Conveyor height flip rinses

- Water, air, or sanitizer options

Applications

- Ideal for pre-rinsing cans or bottles

- Allows for a clean container

- Minimizes dust and other foreign objects inside container

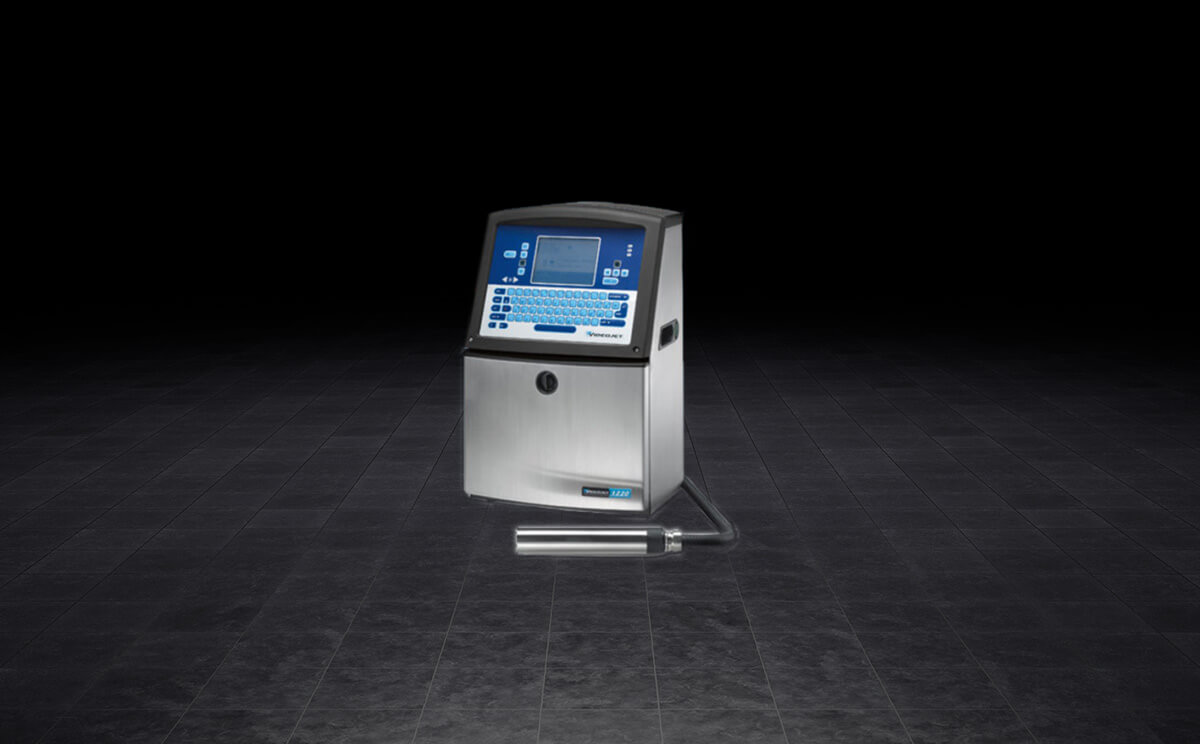

Date Coders

Ink Coder

- Inks – Dye Based

- Maximum Lines of Print – 5

- Message Storage Capability – 100

- Plug and Play Printhead Modules – Included

- USB – Included

Laser Coder

- Permanent codes at speeds of up to 5,000 packages per hour

- No consumables (ink) and low maintenance

- Small, compact footprint

- In-process printing

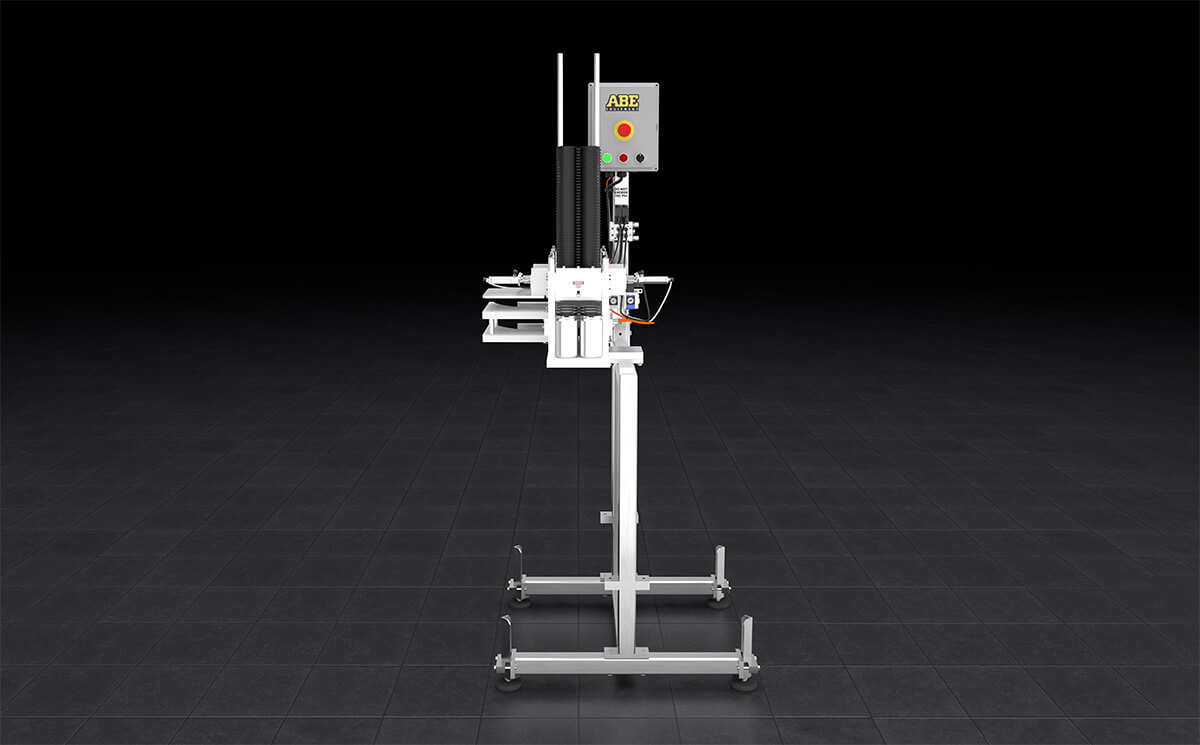

AutoPak

Reduces Labor

- Packs up to 90 cans per minute

- Easily change between 4- and 6-pack carriers

- Easily change between 12 to 16 oz cans

Ease of Use

- Runs on 120v and does not need to be wired by an electrician

- Easy to load for continuous operation

Inline Weigh Scale

The inline weigh station is designed to enhance your packaging quality control by shuttling every seamed can onto a calibrated load cell that reliably measures the total weight. Cans that meet customer-defined standards continue on, and ones that do not are rejected. The weigh station also provides real-time feedback of individual can weights and averages for brewery metrics.

Nitro Dosers

Our Nitro Dosers offer a dynamic dosing feature that allows the user to set a different amount of liquid nitrogen in each can leaving the filler. The doser accommodates up to 10 different dose levels, allowing superior product control. Dynamic dosing compensates for the difference in time between when the cans are filled and seamed. Options are available with and without the use of Widget cans. Talk to your sales representative for details.

Collapsible Feed Table

Features:

- Stainless Steel Construction

- Available in clockwise or counterclockwise rotation

- Collapsible for easy storage and mobility

Compatibility

- Ideal for mobile canning/bottling

- Mates up to other ABE/Norland support equipment

CraftCan Series

CraftCan Series  LabelMax90 Labeling Machine

LabelMax90 Labeling Machine  TruPatriot Filler

TruPatriot Filler  Patriot Fill Station

Patriot Fill Station